Theelectric car looks set to be the future of the global automotive industry. Sales forecasts indicate that electric cars will account for more than 30 percent of market share by 2030, but Is the industrial fabric ready to meet the expected production demands of automakers?

SCS Stampi has been cooperating with the world’s leading automotive companies for over 40 years in the design and manufacture of dies for die casting of metal alloys such as aluminum, zamak, magnesium and brass. Since 1981, the company has developed more than 1100 molds for the Automotive industry specializing in the fields of application: Powertrain, Structural Parts and Truck.

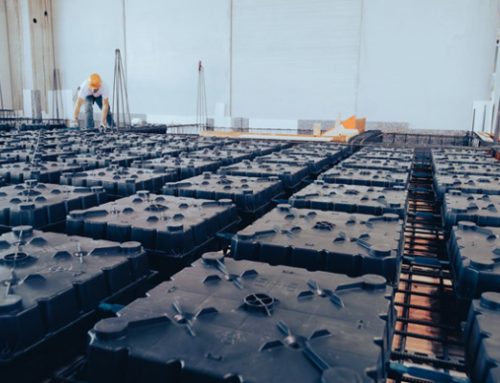

In February 2022, SCS acquired the first order destined for the BEV (Battery Electric Vehicle) world, i.e., exclusively electric-powered vehicles – Specifically, our customer required the supply of an aluminum Battery Housing mold for electric cars.

Battery housings for electric vehicles are intended to contain and protect the battery modules, one of the most expensive and important elements of an electric car but also quite possibly the most delicate. Car manufacturers, in order to improve impact resistance, ensure greater light weight, and increase the thermal conduction needed by the battery’s temperature management system, want to use housings, also called Battery Housing. They can be of various sizes and materials but it would seem that the most suitable material for the coming years is aluminum.

SCS thanks to the synergy between different internal departments and strong collaboration with suppliers is committed to being an all-round partner for all customers, ensuring effective design and high-quality production while meeting agreed delivery times.