PROJECT DEVELOPMENT

The design of each individual mold is executed and coordinated by the Project Manager, who follows it through to completion and validation by the Client. For successful completion, the design is divided into planned phases, each with specific tasks and objectives.

The Customer is involved at various stages of the design process to ensure that the design is developed in accordance with the company’s needs and the requirements to be met by the mold.

Mold making follows a well-defined process that allows for control over every stage of the project.

Reception of the data input of the mold project

Figures involved:

- Technical Manager

- Sales manager

- Project leader

- Selection of design type

The type of design needed within three main types is identified:

- Reduced; improvement of an already completed project at particular critical points or by reducing processing time.

- Executive; project already implemented with no need for improvements.

- Complete; project execution for new parts.

Figures involved:

- Technical Manager

- Project leader

- Activating and closing the outpost

An analysis of all critical issues and possible solutions is carried out. Simulations, calculations and drafts with different design variables and cost alternatives are carried out in the avamproject phase. Final goal the verification and updating of the mold project schedule and completion data.

Figures involved:

- Technical Manager

- Project leader

- Review and verification of the outpost

The prepared avamproject is reviewed and verified together with the Client, assessing cost compatibility and results of the preliminary design.

Figures involved:

- General Management

- Customer

- Technical Manager

- Project leader

- Activation of executive design

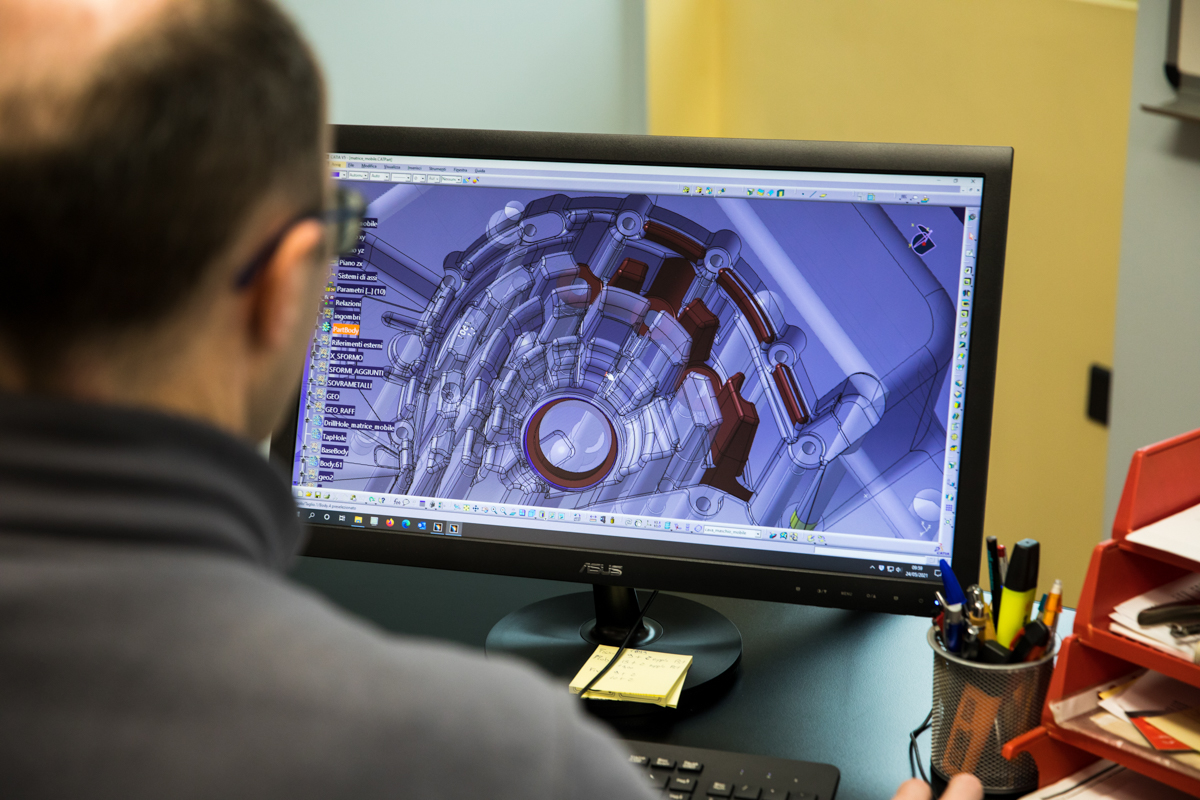

Once the avamproject is concluded, the executive design of the mold is started.

These are the basic steps of the executive design:

- Issue of bill of materials (primary materials);

- Footprint mathematics, with full modeling if not provided by the client, or with verification of client mathematics with analysis and verification;

- Out-of-figure modeling with analysis of critical points (shearability, closure angles, and shoulders) and breakdown of all molding parts (dies, molding courses, cores, and dowels carried over);

- Placement and selection of type and size of extractors;

- Sending to Client for approval regarding extractors, if not indicated in avamproject;

- Modeling and drawing of the casting and wells;

- Study of cooling circuits;

- Completion of the overall.

Figures involved:

- Technical Manager

- Project leader

- Critical design review

Once the executive design has been initiated and the basic characteristics of the mold have been identified, the design undergoes a critical review phase. Correspondence to the design input requirements is checked, and the review is extended by involving the functions involved in the project.

Figures involved:

- Technical Manager

- Project leader

- Design verification

The executive project, once activated and reviewed, sees verification and approval by the General Management and Customer, the last stage before the mold is made.

Figures involved:

- General Management

- Customer

- Implementation and closure of the executive project

The Executive Project verified and approved by Client and General Management is realized to move into the production stage.

The implementation and completion of the executive project includes:

- Completion of the work order list;

- Drafting of parts;

- Critical dimension control plan (if required by the customer);

- Printing of executive drawings;

- Printing drawings for Machine Directive and Mold File;

- Delivery of drawings to the Production Manager;

- Overall printing.

Figures involved:

- Technical Manager

- Project leader

Before being realized, the project passes numerous approvals from different company departments and the final Customer. Only in this way is it possible to obtain a mold that is technically perfect, has excellent performance, and truly meets the customer’s requirements and production goals.

Contact us

Fill out the form to be contacted by one of our consultants as soon as possible.