Automotive is becoming an increasingly complex and technologically advanced industry as automakers relentlessly research and develop innovative structural parts that are lightweight and at the same time functionally and qualitatively better.

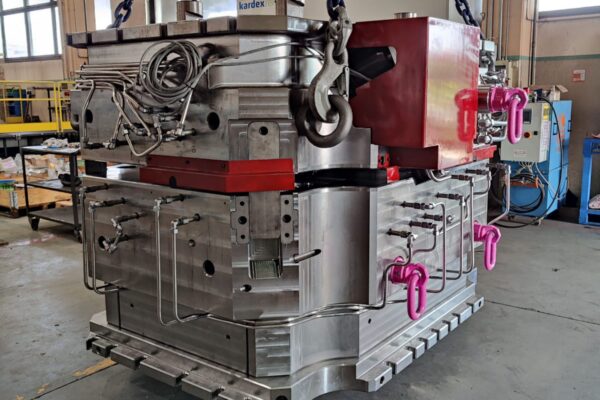

SCS designs and manufactures metal alloy die casting molds for the world’s leading automotive manufacturers. In forty years of operation, it has developed more than 1100 projects, becoming a benchmark for the manufacture of molds for Structural Parts.

In the last quarter of 2021, SCS acquired an order for a mold, weighing more than 39 t, for magnesium die casting of a Front Crossmember intended to be mounted on a model of a well-known car manufacturer.

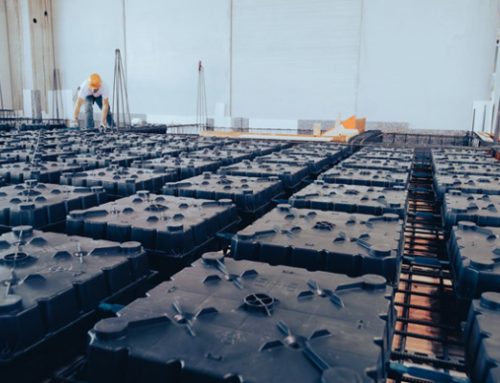

Structural parts are body and chassis components of cars, trucks, and motorcycles generally produced by the die-casting process. Passenger car cross-members are complex parts that contribute greatly to stability and ensure that, in the event of a collision, the passenger compartment is not compressed.

One of the main difficulties in handling these projects is definitely related to the weight and size of the mold. However, this is not a problem for SCS, which can handle molds up to a maximum weight of 55 t./