Since 1981, SCS Srl has been engaged in the production of industrial molds and precision machining for Italian and international companies.

In its 40 years of operation, the company has developed know-how and experience that, combined with a technologically advanced fleet of machines, make it a point of reference for the development and implementation of projects for the automotive, industrial, furniture, construction, electrical and nautical sectors.

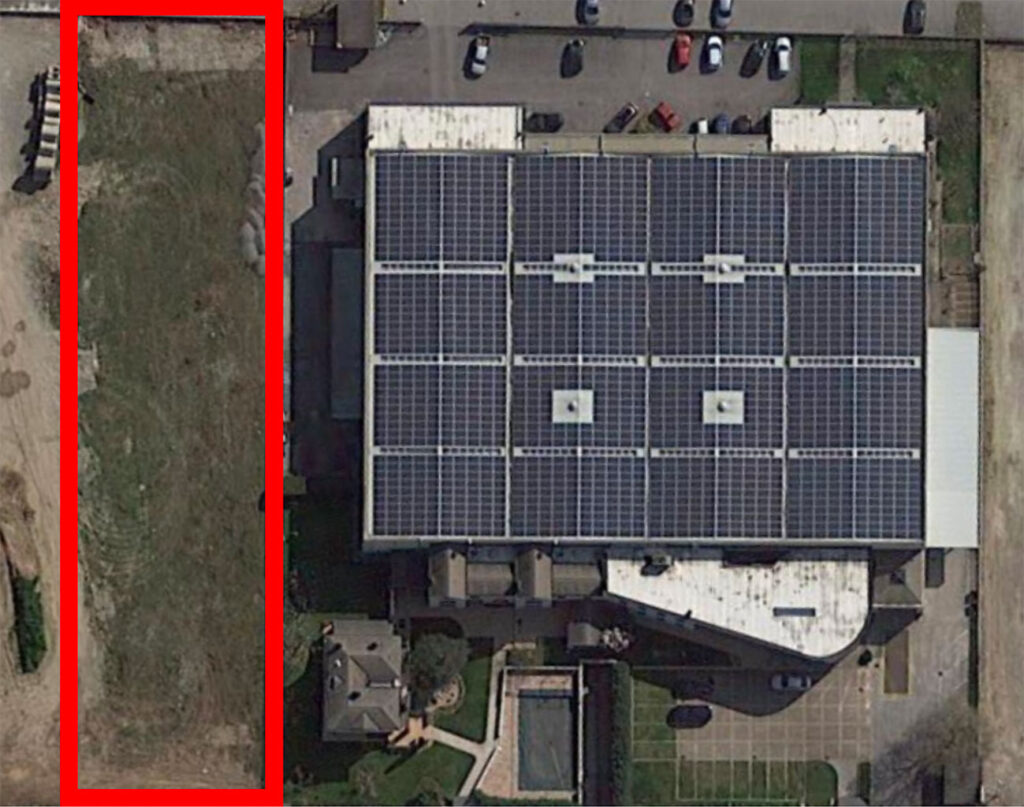

The design is managed by SCS with a co-engineering process, involving the End Customer and the different internal departments, so that timing and processing steps are precisely and reliably defined. Our quality management system is ISO 9001 certified and is deeply integrated into every stage of the production process. Attention to environmental sustainability is also one of our priorities: we are ISO 14001 certified and have a photovoltaic system that allows us to produce the energy needed for our production processes while respecting the environment.

⌖ ADDRESS

Via Milano 12, 25037 Pontoglio

☏ PHONE

+39 030 7470513

info@scsstampi.it

“Nothing in the world was made without passion.”

Our company over the years

1981

SCS was founded in Pontoglio in 1981 thanks to the resourcefulness and passion of founder Mario Rodegari. The company, from the very beginning, designs and builds molds for various industries with the goal of providing the highest quality products designed to stand the test of time.

1998

The company continues to grow and in 1998 moved to a new 8,000-square-meter operational headquarters with an innovative and revolutionary design.

2003

The ability to consistently and comprehensively meet customer expectations is embodied in ISO 9001 certification.

2007

The company with a view to future expansion purchases an area of 2,000 square meters adjacent to the current industrial site.

2017

The company, which is very attentive to environmental sustainability, invests in the installation of a 400.00 KW photovoltaic system capable of generating clean energy for about 50 percent of its production processes.

2018

Attention to the environment is embodied in obtaining ISO 14001 certification.

2019

Significant investments lead the company to meet the challenge of digitization in the perspective of Industry 4.0.

Contact us

Fill out the form to be contacted by one of our consultants as soon as possible.