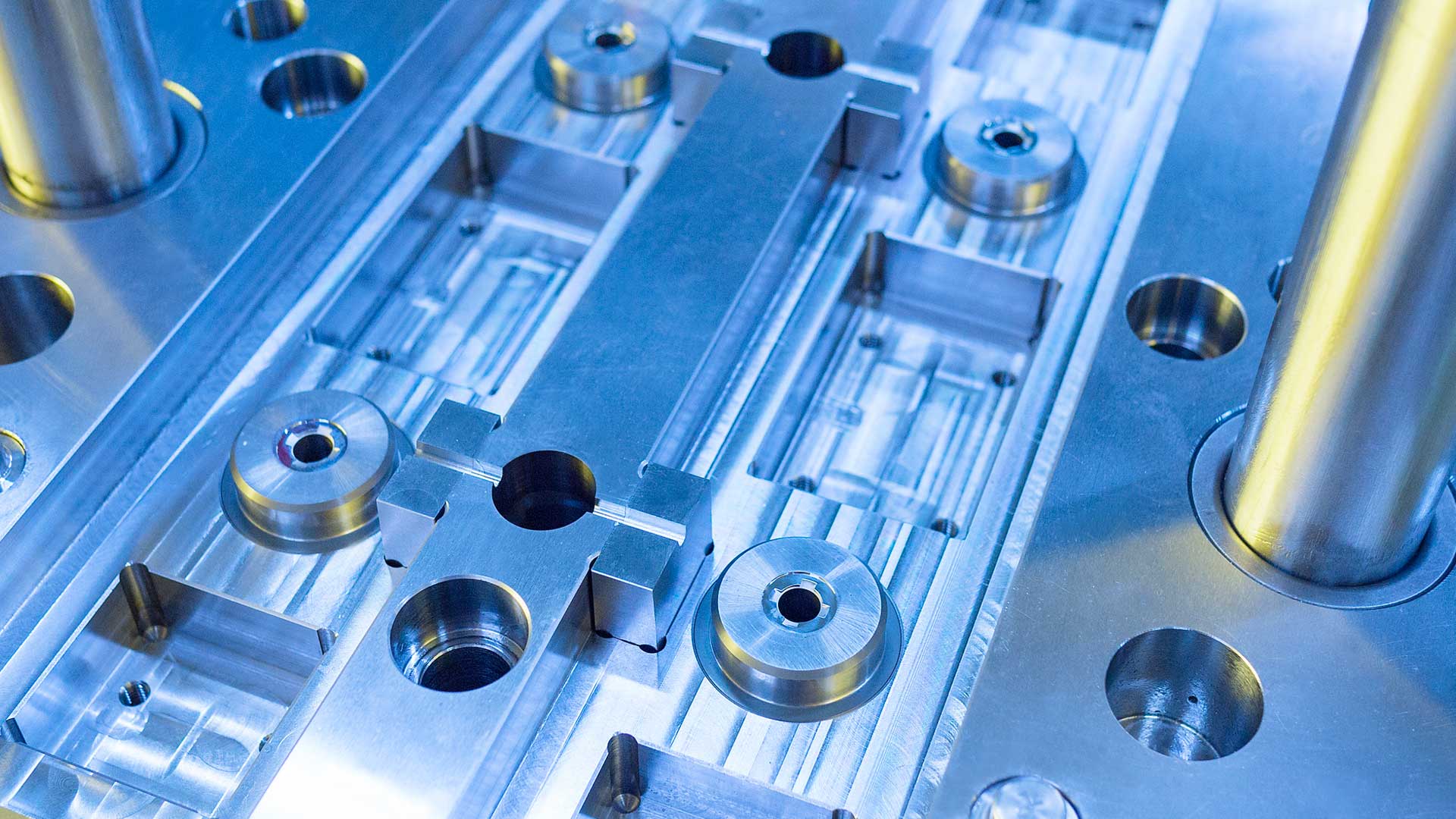

MOLD MAKING

The executive project carried out as approved by General Management and Client thus moves into the implementation phase.

The mold making process starts from material procurement in the company, with various quality checks and tests to meet the requirements specified by the Customer at the design stage.

Mold making follows several processes:

- Steel block preparation;

- Drilling and creation of cooling circuits;

- Roughing of figure impressions with milling and turning machining;

- Heat treatments performed by certified suppliers;

- Finishing with completion of milling in details;

- Dimensional checks on individual mold components.

This process is specific and particular depending on the purpose of the mold, whether for die-casting or injection molding.

Contact us

Fill out the form to be contacted by one of our consultants as soon as possible.